pioneer machinery

Event logging system

The principle of operation of the event logging system resides on the RFID sensors which are installed in a number of key locations along the production line. These RFID sensors (such as bracelets worn by the operators or tokens installed on the machines) allow production events to be simultaneously uploaded onto Pioneer SmartFA platform in a well-organized and sequential manner. In addition to recording the data in a digital form, this real-time upload of events prevents further errors or inaccuracies during reporting of events.

pioneer machinery

Features of event logging system

Pioneer machinery

Benefits of event logging system

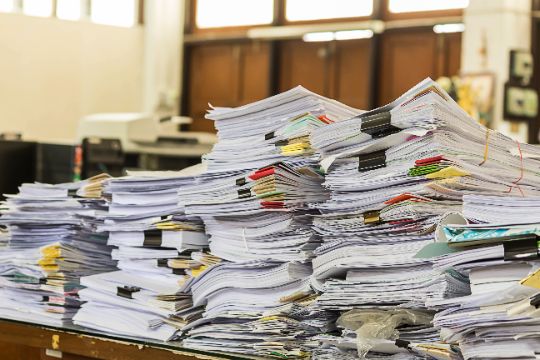

90% decrease in paper

- decrease in paper usage by using RFID system

without

delay

- Events uploaded onto Pioneer SmartFA in real-time without delay.

well - organized database

- Data is stored in a well-organized database in sequence.

Related applications

CRM form will load here